High pressure pump

The basis of operation of a reverse osmosis desalination system is based on creating a pressure in the opposite direction of the osmotic pressure of the water.

The higher the amount of salinity and solutes in water, the higher its osmotic pressure, and naturally, it is necessary to create more pressure to overcome the osmotic pressure. The task of creating the necessary pressure for water to pass through the reverse osmosis membrane in an industrial water treatment system is the responsibility of the high pressure pump. The high pressure pump of an RO device is selected by considering the required flow rate and pressure obtained from the desalination device design.

The water salinity is also effective in determining the type of pump, and the higher the salinity and water solutes, the higher the need to choose a high pressure pump with corrosion resistance.

For an RO desalination machine, vertical and horizontal floor pumps, piston pumps and some other types of special pumps are usually used.

Multistage pumps

Stage pumps are a group of centrifugal pumps that consist of two or more impellers connected in series. The water pressure increases a bit as it enters each stage of a multistage pump. The more the number of floors of a multi-stage pump, the higher the final pressure of the output water.

Depending on whether they have a horizontal or vertical shaft, multistage pumps are divided into two categories: horizontal multistage pump and vertical multistage pump.

Some prominent brands of floor pumps used in desalination devices are listed below.

GRUNDFOS Denmark

LOWARA Italy

DAB Italy

WILO Germany

PENTAX Italy

EBARA Japan

LEO China

CNP China

Piston Pumps

A piston pump, also called a car wash pump, is a positive displacement pump in which the water in its cylinders is compressed by the piston, thus increasing its pressure. In a piston pump, the electric motor is connected to the piston by a crank and drives it.

Piston pumps can provide a wide range of pressure for desalination and water treatment operations. The piston pump has less power than the centrifugal pump and is mostly used when the water flow with low flow rate is supposed to have high pressure.

Some prominent brands of piston pump manufacturers used in industrial water purification systems and desalination devices are listed below.

CAT - Italy

BERTOLINY Italy

INTERPUMP GROUP Italy

ANNOVI REVERBERI Italy

Danfoss Pumps Denmark (App series)

Danfoss APP series high pressure pumps are axial piston positive displacement type pumps that move a constant amount of water in each cycle. Danfoss APP series pumps are specially designed for RO desalination device and can support a minimum flow rate of 0.6 m3/h to a maximum of 86 m3/h.

Using water instead of oil as a lubricant, low maintenance costs, minimal energy consumption, easy installation and use, the possibility of vertical or horizontal installation, and also being made of duplex and super duplex stainless steel. Duplex) has made Danfoss APP series pumps the most reliable and best option for use as high pressure pumps in marine desalination systems.

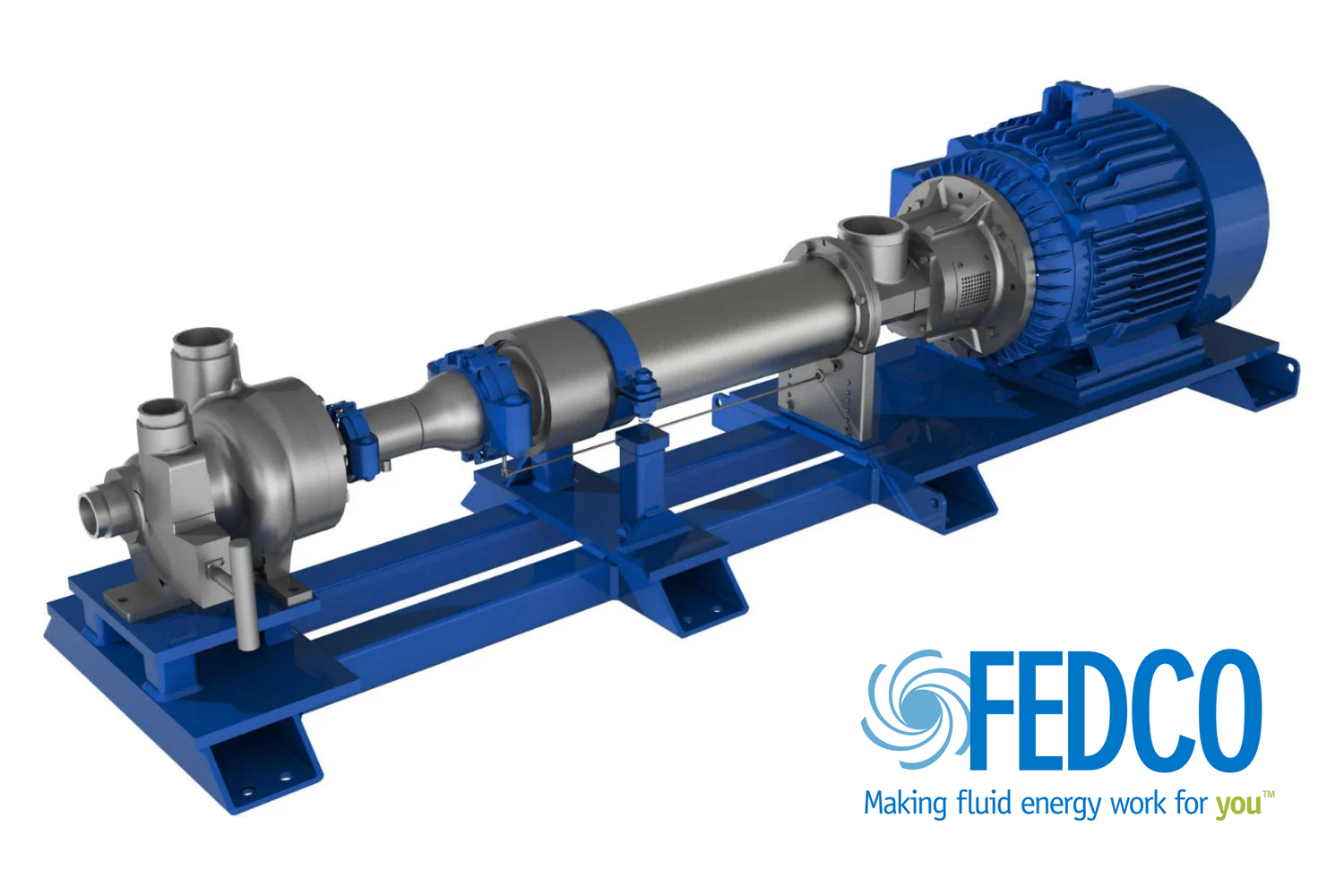

FEDCO Pumps USA (MSS series)

FEDCO MSS series high pressure pumps are horizontal floor type pumps that are specially designed and manufactured for the purification and desalination of sea water and all types of brackish water. These pumps provide a minimum flow rate of 7.5 m3/h and a maximum of 295 m3/h and a maximum pressure of 83 bar.

Fedco's MSS series pumps are made of 316 stainless steel, and their impeller and diffuser are electropolished and passivated, which greatly increases the resistance of these pumps against corrosion. Among the other advantages of MSS series pumps, we can point out that there is no need for lubricants and the cooling of the bearings with incoming water, which eliminates the limitation of using the pump at room temperature.